The Business Case Challenge

Every project manager knows the frustration: you’re convinced that better progress tracking technology will improve outcomes, but leadership wants numbers. Hard ROI. Payback periods. NPV calculations.

This guide provides exactly that—a structured approach to quantifying the value of automated progress tracking, backed by industry data and real-world case studies.

Understanding the Cost of Poor Progress Visibility

Before calculating ROI, we must understand what poor progress tracking actually costs:

Direct Costs

Delayed Issue Detection When problems are discovered late, remediation costs multiply:

- Week 1 detection: $10,000 fix

- Week 4 detection: $50,000 fix

- Week 8 detection: $200,000+ fix

Industry data shows the average megaproject discovers schedule issues 23 days after they occur. Earlier detection alone justifies significant investment.

Rework Due to Miscommunication Without accurate progress data, coordination failures lead to rework:

- Installing MEP before structural corrections

- Finishing areas before inspection

- Mobilizing trades to incomplete areas

The Construction Industry Institute estimates rework at 5-12% of project costs.

Inefficient Resource Allocation Without visibility into actual progress:

- Equipment sits idle waiting for work

- Crews are mobilized to areas not ready

- Materials arrive before storage is prepared

Studies show 15-30% of construction labor time is non-productive due to waiting, rework, and inefficiency.

Indirect Costs

Schedule Delays Delayed projects incur:

- Extended general conditions ($50K-$200K/week typical)

- Liquidated damages (varies by contract)

- Opportunity cost of delayed revenue

- Team and subcontractor retention challenges

Disputes and Claims Poor documentation leads to:

- Subcontractor claims for owner-caused delays

- Disputes over completion percentages

- Change order negotiations without baseline

- Litigation costs

Reputation Damage Consistently late or over-budget projects affect:

- Future bid competitiveness

- Client relationship

- Talent retention

- Market position

Quantifying Progress Tracking Benefits

Benefit Category 1: Faster Issue Detection

Formula:

Annual Savings = (Issues/Year) × (Days Saved) × (Cost/Day of Delay)Example:

- 24 significant issues per year (2/month)

- 14 days faster detection with automated tracking

- $15,000 average cost per day of delay per issue

24 × 14 × $15,000 = $5,040,000 annual savingsBenchmark Data:

- Manual tracking detects issues 18-25 days late on average

- Automated tracking detects issues 3-7 days late on average

- Improvement: 11-18 days faster detection

Benefit Category 2: Reduced Survey/Documentation Labor

Formula:

Annual Savings = (Hours/Week Saved) × (Weeks/Year) × (Loaded Labor Rate)Example:

- 40 hours/week on manual surveys and reports

- With automation: 8 hours/week

- 52 weeks per year

- $85/hour loaded labor rate

32 × 52 × $85 = $141,440 annual savingsBenchmark Data:

- Traditional survey: 20-40 hours/week per project

- Automated capture: 4-8 hours/week per project

- Typical reduction: 70-85%

Benefit Category 3: Reduced Rework

Formula:

Annual Savings = (Annual Construction Volume) × (Rework %) × (Reduction %)Example:

- $200M annual construction volume

- 7% current rework rate

- 30% reduction from better coordination

$200M × 0.07 × 0.30 = $4,200,000 annual savingsBenchmark Data:

- Industry average rework: 5-12% of project cost

- Better progress visibility typically reduces rework by 25-40%

Benefit Category 4: Improved Productivity

Formula:

Annual Savings = (Labor Spend) × (Non-Productive %) × (Improvement %)Example:

- $80M annual labor spend

- 20% non-productive time (waiting, searching, rework)

- 15% improvement from better coordination

$80M × 0.20 × 0.15 = $2,400,000 annual savingsBenchmark Data:

- Non-productive time ranges 15-35% in construction

- Information-driven improvements typically yield 10-20% gains

Benefit Category 5: Schedule Compression

Formula:

Annual Savings = (Projects/Year) × (Days Saved) × (Daily GC Cost)Example:

- 4 major projects per year

- 12 days saved per project through better tracking

- $35,000 daily general conditions cost

4 × 12 × $35,000 = $1,680,000 annual savingsBenchmark Data:

- Projects with real-time tracking complete 5-15% faster

- On a 24-month project, that’s 1-3 months saved

Total ROI Calculation

Sample Annual Benefits Summary

| Benefit Category | Conservative | Moderate | Aggressive |

|---|---|---|---|

| Faster Issue Detection | $2,500,000 | $5,000,000 | $8,000,000 |

| Labor Savings | $100,000 | $140,000 | $200,000 |

| Reduced Rework | $2,000,000 | $4,200,000 | $6,500,000 |

| Productivity Gains | $1,200,000 | $2,400,000 | $3,600,000 |

| Schedule Compression | $840,000 | $1,680,000 | $2,500,000 |

| Total Annual Benefit | $6,640,000 | $13,420,000 | $20,800,000 |

Typical Investment Costs

| Cost Category | Annual Cost |

|---|---|

| Software licensing | $150,000 - $400,000 |

| Hardware (drones, cameras) | $50,000 - $150,000 |

| Implementation & training | $75,000 - $200,000 |

| Ongoing support | $50,000 - $100,000 |

| Internal resources | $100,000 - $200,000 |

| Total Annual Investment | $425,000 - $1,050,000 |

ROI Metrics

Payback Period:

Investment ÷ Monthly Savings = Months to Payback

$750,000 ÷ ($13,420,000 ÷ 12) = 0.67 monthsAnnual ROI:

(Annual Benefit - Annual Cost) ÷ Annual Cost × 100

($13,420,000 - $750,000) ÷ $750,000 × 100 = 1,689%3-Year NPV (at 10% discount rate):

Year 1: $12,670,000 ÷ 1.10 = $11,518,182

Year 2: $12,670,000 ÷ 1.21 = $10,471,074

Year 3: $12,670,000 ÷ 1.33 = $9,526,316

NPV = $31,515,572Real-World Case Studies

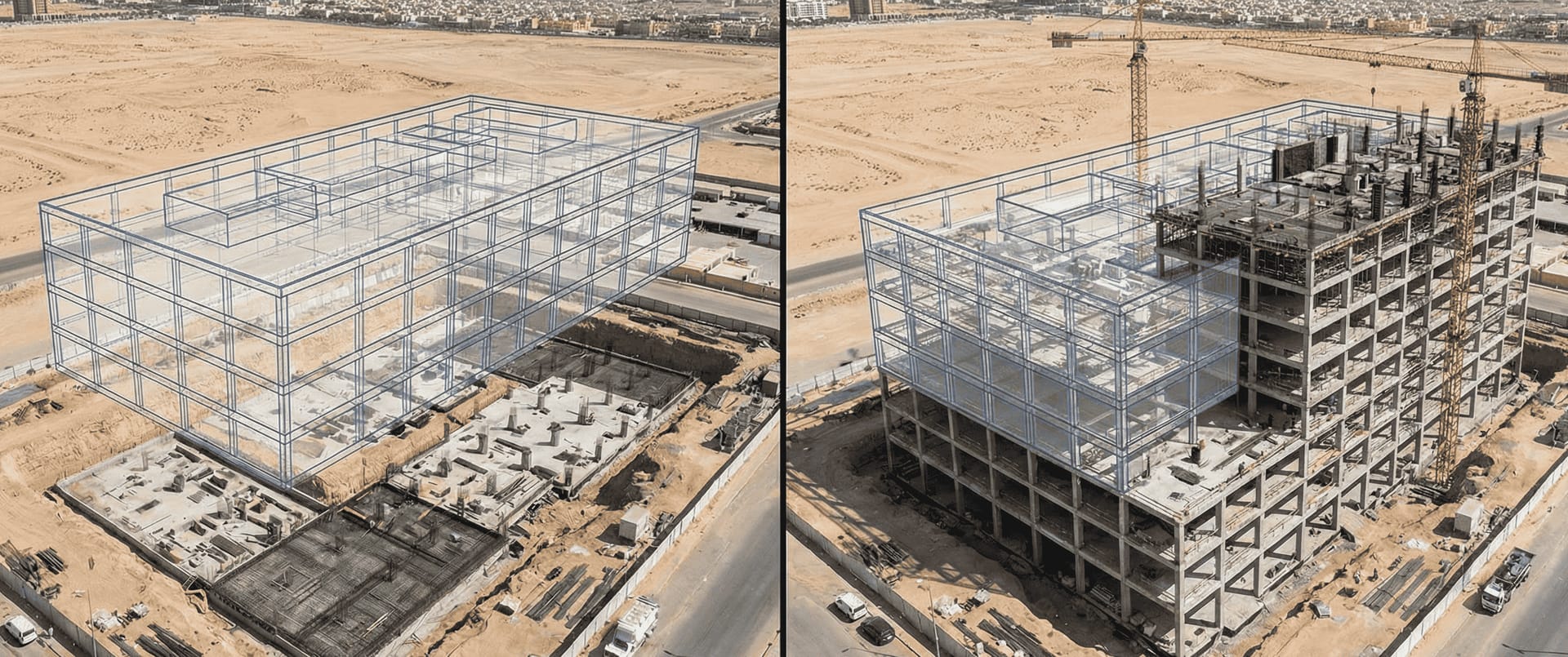

Case Study 1: Saudi Megaproject Developer

Profile:

- 5 active projects totaling $3.2B

- Traditional survey-based progress tracking

- 45-person project controls team

Implementation:

- Drone-based progress capture weekly

- AI-powered progress measurement

- Integration with P6 scheduling

Results (Year 1):

- 62% reduction in survey labor hours

- 34% faster issue identification

- 28% reduction in schedule claims

- $18.4M documented savings

- 6-week payback period

Case Study 2: Regional Contractor

Profile:

- 12 projects, $400M annual volume

- Excel-based progress tracking

- Limited visibility for leadership

Implementation:

- Mobile photo documentation

- Automated progress reports

- Dashboard for executives

Results (Year 1):

- 45% faster progress reporting

- 23% reduction in rework

- 89% reduction in progress disputes

- $3.1M documented savings

- 4-month payback period

Case Study 3: Infrastructure Authority

Profile:

- Highway and bridge portfolio

- Multiple contractors requiring oversight

- Public accountability requirements

Implementation:

- Standardized drone documentation

- AI progress measurement against milestones

- Public-facing progress dashboard

Results (Year 1):

- 100% on-time milestone verification

- 56% reduction in payment disputes

- 78% faster progress certification

- $7.8M documented savings

- 3-month payback period

Building Your Business Case

Step 1: Baseline Current State

Document your current reality:

- Hours spent on progress documentation weekly

- Average delay in issue detection (survey subcontractors)

- Recent rework incidents and costs

- Schedule overruns in past 2 years

- Dispute costs and resolution time

Step 2: Identify Applicable Benefits

Not all benefits apply equally to every organization. Prioritize:

- Largest current pain points

- Most quantifiable improvements

- Quickest wins for credibility

- Strategic alignment with company goals

Step 3: Develop Conservative Estimates

Leadership respects realistic projections:

- Use industry benchmarks as starting points

- Adjust for your specific context

- Include only benefits you can explain and defend

- Build in contingency for adoption challenges

Step 4: Define Implementation Approach

Show you’ve thought through execution:

- Pilot project selection criteria

- Rollout timeline and phases

- Resource requirements

- Risk mitigation strategies

- Success metrics and checkpoints

Step 5: Present with Confidence

Structure your presentation:

- Problem statement with real examples

- Proposed solution overview

- Expected benefits (quantified)

- Investment requirements

- ROI summary and payback

- Implementation plan

- Risk analysis

- Recommendation and next steps

Common Objections and Responses

“We’ve tried technology before and it didn’t work.” Focus on what’s different: better technology, clearer implementation plan, committed change management, defined success metrics.

“Our projects are unique; benchmarks don’t apply.” Propose a pilot to generate your own data. Offer to validate assumptions before full commitment.

“We don’t have budget this year.” Calculate the cost of waiting. If you’re losing $1M/month to poor tracking, every month of delay costs real money.

“Our teams won’t adopt new tools.” Address change management directly. Include training, incentives, and gradual rollout in your plan.

“The technology isn’t proven.” Reference case studies, arrange site visits, request pilot program with minimal commitment.

Need help building your business case? Future Intelligence provides ROI assessments and pilot programs for construction progress tracking. Contact us for a customized analysis.